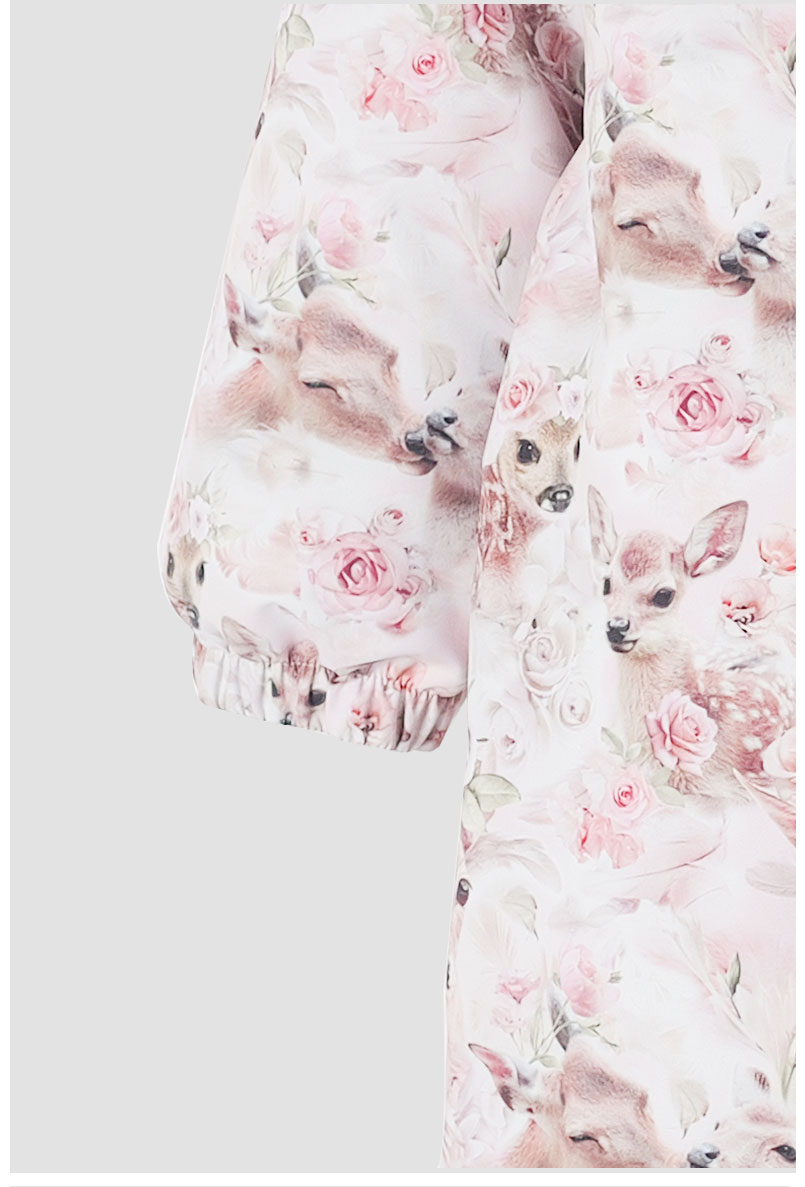

Print Kid’s Overall

Waterproof and windproof puffer overall with heavy padding and an all over print. Featured with a water-repellent BIONIC-FINISH® ECO coating free from fluorocarbons and other hazardous chemicals such as formaldehyde and paraffin.

All the main raw materials are made from 100% recycled polyester.

Function: Fabric is water resistant with 10000mm water columns, breathable: 7000 g/m2/24h

Key feature: Durable, high abrasion, high tension, high tearing strength

Products Categories

Get A Free Quote

Technical detail of durable kid's outdoor overall

| Shell fabric | 100%recycled polyester, bionic water repellent finishing, PU laminated water proof/breathable 10K/7K | ||

| Filling | 100% recycled polyester | ||

| Lining: | 210T 100% recycled polyester | ||

| Hood edge | Faux fur | ||

| Zipper | 5# YKK Metalic vislon zipper | ||

| Snap button | YKK 1.2cm metal button | ||

| Hood | Removed hood | ||

| Parameter | Test method | requirements(mg/kg) | Result |

| Chemical Test requirement | |||

| Free and Hydrolised Formaldehyde | EN ISO 14184-1:2011 | Max.16 | <16 |

| Dimethylformamide (DMFa) | GC-MS | <30 | 15 |

| Physical test requirement | |||

| Abrasion resistance | BS EN ISO 12947-2/:2016, Matindale Abrasion and pilling tester, pressure used : 9 kpa, load 80000 cycles |

> 80000 | |

| Tear properties of fabrics | ISO 13937- 2:2000/ BS EN ISO 13937-2:2000, Signle tear method |

Across warp (N): 94.2 | |

| Across weft (N): 95.4 | |||

| Tensile properties | ISO 13934-1:2013 / BS EN ISO 13934-1:2013, 5-CM Strip test, tensile test machine cre |

Warp (N):1300 | |

| Weft (N):1000 | |||

| Elongation – Warp (N):30.5 | |||

| Elongation – Weft (N):36.5 | |||

| Abrasion persistance of taped fabrics | BS EN ISO 12947-2/:2016, Matindale Abrasion and pilling tester, pressure used : 9 kpa, load 80000 cycles |

After taped: 50000 |

Detail of printed overall by Lime China

Get Free Quote of Print Kid’s Overall

Related Products

Related Blog

OEM jackets to empower your brand